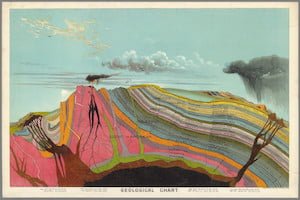

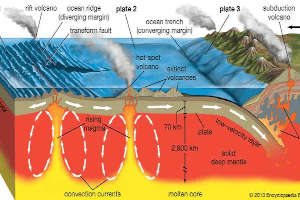

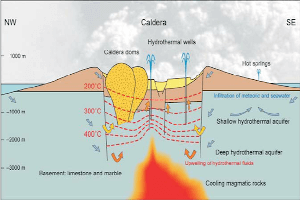

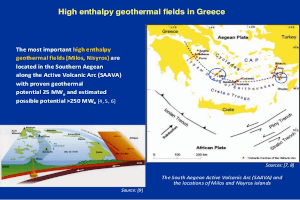

The main characteristics that dictate the possible uses and economical value of geothermal fluids are temperature, usable volume and chemical composition. Temperature is the most important property of all. The location of the geothermal field is also highly important, as the hot fluid cannot be transported to excessive distances (tens of kilometers).

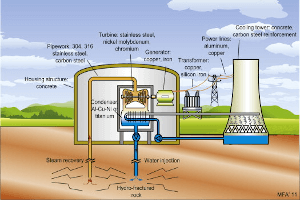

Electric power generation is the main use of medium / high temperature fluids. As regards high temperature fluids, geothermal steam is used in conventional units, using a process also applied to fossil fuels and nuclear power. The essential difference is that geothermal steam input pressure in the generator turbine cannot be regulated at will; it is dictated by the characteristics of the reservoir. Furthermore, geothermal steam efficiency is low. Only approximately 10% of the thermal energy extracted from boreholes can be converted to electric power. A general estimate is that two kilograms of steam per second are necessary to produce 1 MW of electric power.

As regards fluids with temperatures between 85 and 175°C, the binary or Rankine cycle with organic fluid is applied. Binary systems are small, modular plants with rated capacity less than 3 MWe. The binary cycle represents a higher investment compared to conventional electrical power plants; however it poses remarkable environmental benefits as it operates as a closed circuit and fluids are not exposed to the environment; instead they are immediately reentered to the source.

Thermal power of fluids is commonly used (after the generation of electrical power) for parallel direct applications (i.e. desalination, heating of buildings etc), thus the efficiency of the entire system is substantially improved.

Direct utilization of geothermal fluids is much more efficient. For instance, to provide heat to buildings, assuming an initial water temperature of 80°C and a discharge temperature of 20οC, efficiency rate amounts to 75%.

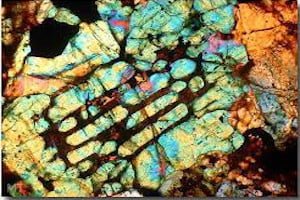

Commonly, immediate use of geothermal water is not feasible due to its chemical composition. In – situ water often contains salts and other contaminants. High – salinity fluids often pose precipitation – salt contamination problems to the extraction – production system; special techniques have been adopted to deal with such problems.

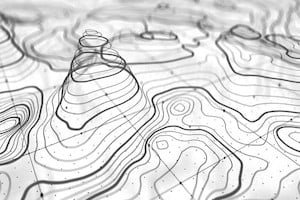

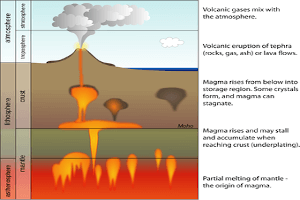

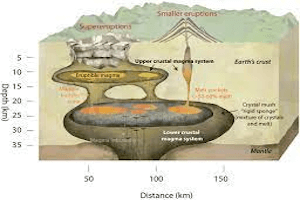

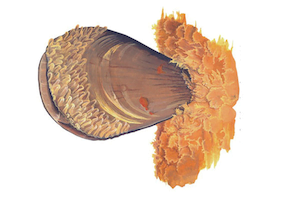

Geothermal fluids are commonly extracted from boreholes. Such boreholes for electrical power generation range between 1500-2500 meters deep, though there are some geothermal boreholes reaching 4 kilometers deep. The cost of a deep geothermal borehole in a high – temperature volcanic setting amounts to approximately €1.5 million. Construction time is 2-3 months.

Boreholes for low temperature fluids are usually significantly shallower and their construction is a lot cheaper. They usually reach a few hundred meters deep and rarely exceed 1000 meters.